In the age of water and steam-powered mills, industrial power transmission was a far cry from the advanced systems we know today. Before the era of electricity, these mills depended on a network of mechanical parts to generate the power needed to run their operations.

Central to this system was the spinning shaft, suspended from the ceiling, which transmitted energy throughout the building. At the heart of these operations was a critical, often overlooked component—the slip bearing.

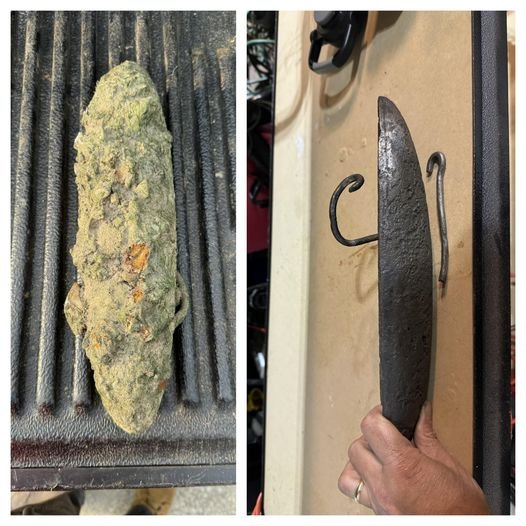

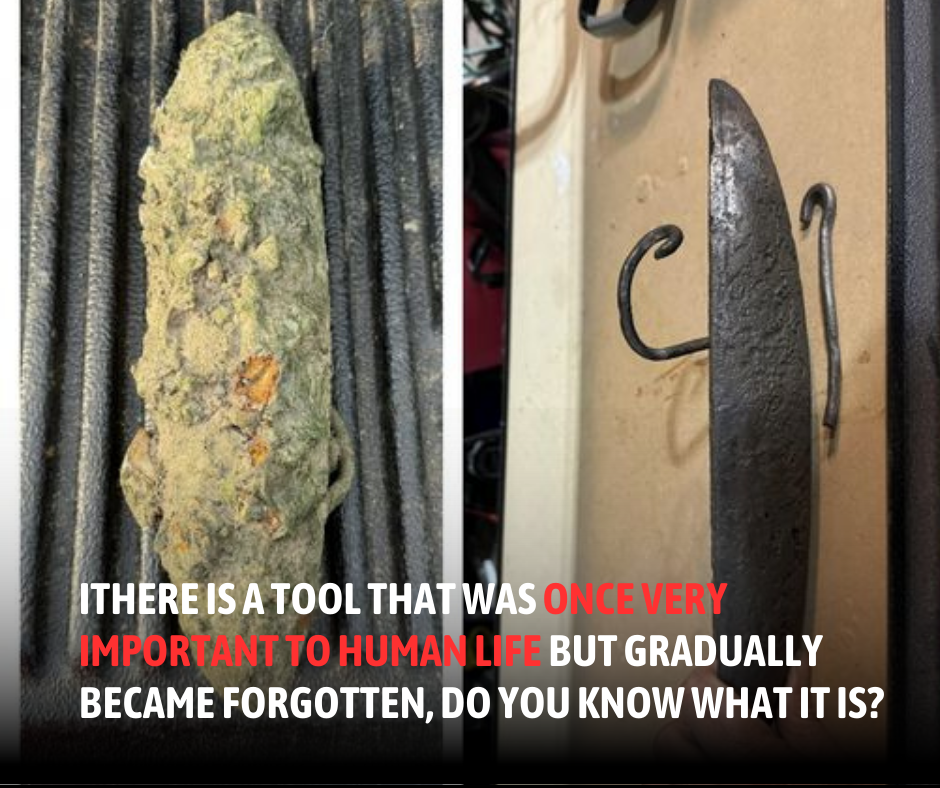

What Was a Slip Bearing?

A slip bearing, also referred to as a plain bearing, played a pivotal role in the machinery of early industrial mills. Unlike modern roller bearings, which rely on balls or rollers to minimize friction, slip bearings functioned using direct contact between two metal surfaces.

These bearings were made from a soft metal alloy, known as bearing metal, that was deliberately designed to have a lower melting point than the harder metals used in the shaft and support structure, called hanger rods.

Slip bearings were simple yet effective, but their performance hinged on proper lubrication. Without adequate oil or grease, the friction between the bearing and the shaft would increase, leading to dangerous levels of heat. These bearings were essential to the smooth running of machinery in mills and factories during the industrial revolution.

How Slip Bearings Kept Mills Running Smoothly

In the fast-paced environment of early mills, ensuring that every part of the machinery worked seamlessly was a priority. The key to keeping slip bearings functional was constant lubrication.

Oil and grease played a critical role in reducing friction between the metal surfaces of the bearing and the rotating shaft. If lubrication was insufficient, the resulting friction could cause the bearing metal to overheat, soften, and eventually melt—a catastrophic outcome that could halt operations and even endanger workers.

To prevent these failures, mills employed a simple yet ingenious tool to catch the excess oil and grease used to lubricate the bearings. This tool ensured that the bearings were consistently supplied with the lubrication they needed, helping to reduce friction and prevent overheating.

The Importance of Lubrication

Lubrication was more than just a maintenance routine—it was a safeguard against potential disaster. When the grease or oil ran low, the friction between the shaft and the slip bearing would cause the temperature to rise rapidly.

In some cases, this heat could melt the bearing metal, causing molten metal to drip from the ceiling, creating a hazardous environment for workers below.

But the risks didn’t stop there. In mills constructed primarily from wood, the heat generated by a failing bearing could ignite the structure, leading to devastating fires. In fact, improper lubrication was one of the most common causes of accidents in early mills.

The simple grease-catching tool, though humble, was crucial in preventing these dangerous incidents.

The Dangers of Friction: A Lesser-Known Hazard

The consequences of failing to properly lubricate slip bearings were more severe than many realized. A bearing running dry not only increased the risk of fire but also led to mechanical failures that could bring entire operations to a standstill.

When the bearing metal melted, it often meant replacing significant parts of the machinery—a costly and time-consuming process for mill operators.

In some cases, workers would be forced to halt production entirely while waiting for replacement parts, leading to lost revenue and productivity.

These issues underscore the importance of seemingly minor tools like grease catchers, which played a critical role in maintaining the day-to-day function of industrial mills.

A Glimpse Into Industrial Ingenuity

While it might seem like a simple tool today, the grease-catching device used in mills was a testament to the ingenuity of early industrialists. They had to come up with practical solutions to keep their machinery running smoothly, long before the advent of modern engineering and technology.

The slip bearing and its lubrication system highlight how far we’ve come in terms of industrial innovation. In the early days of the Industrial Revolution, mills were at the forefront of technological progress, and their success depended on tools that were both efficient and effective in maintaining equipment.

Without tools like the grease catcher, these operations would have faced constant interruptions due to mechanical failures, overheating, and even fire hazards.

The Legacy of Slip Bearings

Though slip bearings have largely been replaced by more advanced mechanisms, their role in the history of industrial technology cannot be understated. These bearings were foundational in the operations of early mills, helping to power the massive machinery that drove the Industrial Revolution.

The slip bearing serves as a reminder of the challenges mill operators faced and the solutions they devised to overcome them.

Today, modern bearings are far more efficient, utilizing advanced materials and designs that minimize friction and maximize performance. However, the legacy of slip bearings lives on as a symbol of industrial progress.

The innovations made during that time paved the way for the technological advancements we enjoy today, from automated factories to cutting-edge manufacturing equipment.